Here's A Quick Way To Solve A Info About What Is ROM PLC

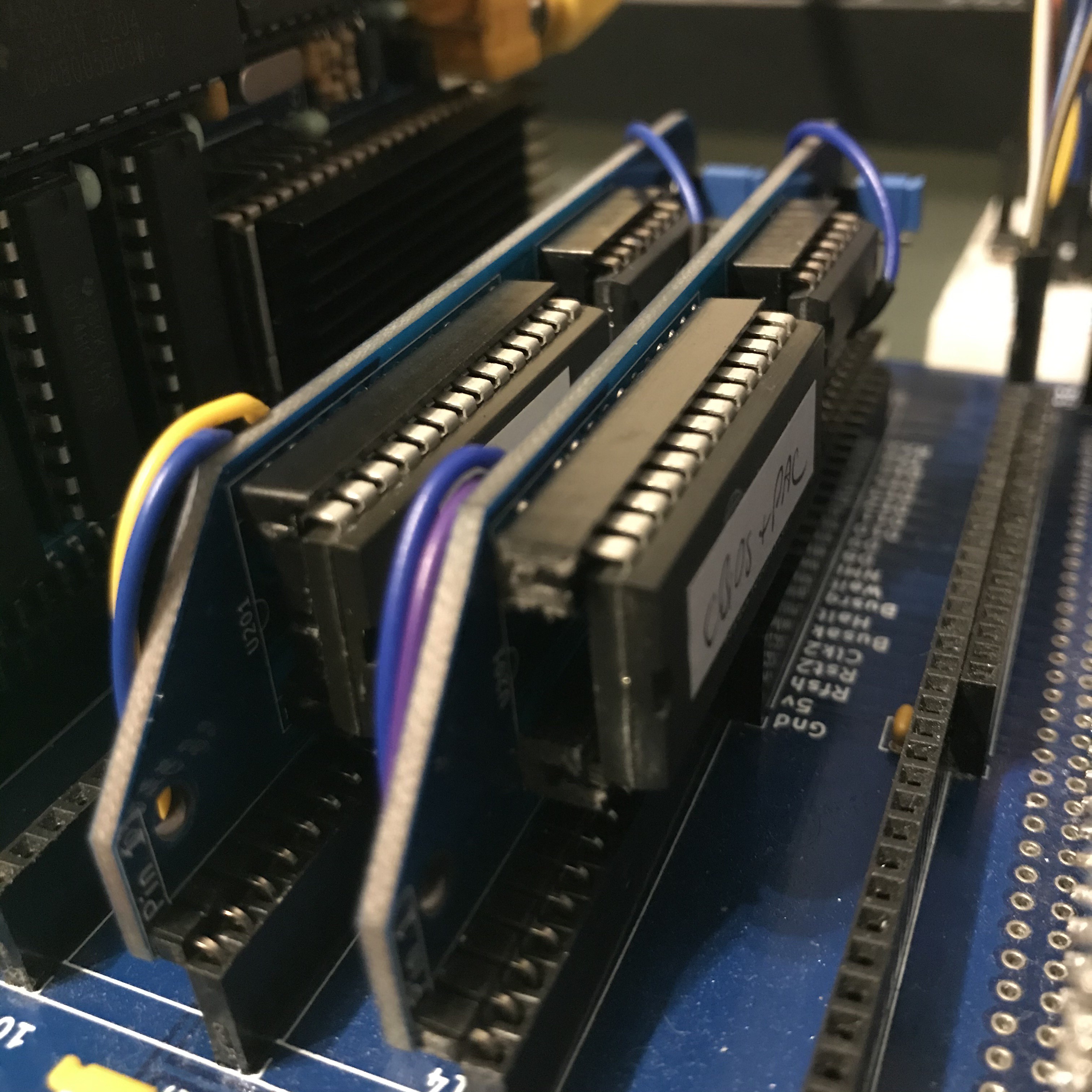

More On RAM And ROM A Working* System! Details Hackaday.io

Unlocking the Secrets of ROM in PLCs

1. What's the Deal with ROM in PLCs Anyway?

So, you've stumbled upon the term "ROM PLC" and are probably scratching your head, wondering what it all means. No worries, we've all been there! Simply put, ROM in the context of a Programmable Logic Controller (PLC) stands for Read-Only Memory. It's a special type of memory that stores instructions and data that the PLC needs to operate, and here's the kicker — it can't be easily changed or erased. Think of it as the PLC's foundational knowledge, its built-in instruction manual. It's the core software that allows your PLC to function!

Imagine a cookbook where the recipes are permanently printed; you can read and follow them to cook up a storm, but you can't exactly scribble out a recipe and replace it with your grandma's secret sauce. That's ROM in a nutshell. This inherent immutability is crucial for the PLC's reliability. It ensures the PLC starts up correctly every time, executing the same core functions consistently. Without ROM, things could get a bit chaotic!

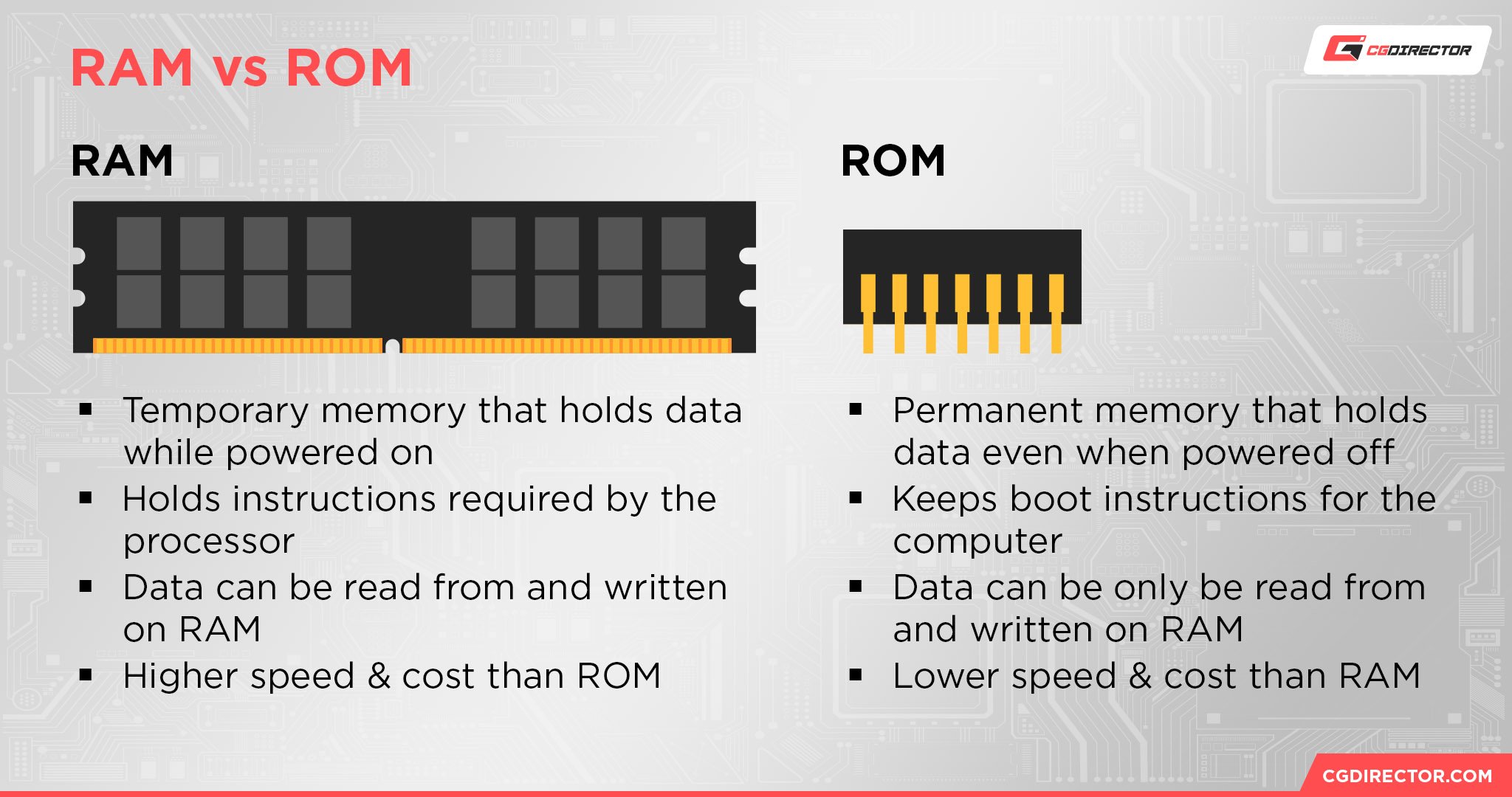

Unlike RAM (Random Access Memory), which is volatile and loses its data when power is off, ROM is non-volatile. This means it retains its information even when the PLC is turned off or loses power. This is essential for storing the operating system, boot sequences, and other critical firmware that the PLC needs to function upon start-up. It's what separates a powerful automation tool from a useless brick!

ROM in PLCs, while typically not user-programmable, provides the fundamental software that the PLC runs on. It's the rock-solid base upon which all your custom programs and applications are built. This stability and reliability are key factors in the industrial environments where PLCs are frequently used, where consistent and predictable operation is not just preferred, it's absolutely vital.

What Is A PLC (Programmable Logic Controllers) Comprehensive Guide

The Role of ROM in PLC Functionality

2. How Does ROM Actually Help the PLC Do Its Job?

Okay, so we know ROM holds permanent information. But how does that translate into actual, practical PLC operation? Well, ROM is usually the home for the PLC's operating system (OS), its basic input/output system (BIOS, or something similar), and other essential firmware. These components work together to manage the PLC's hardware, handle communication with other devices, and execute the user-defined programs.

Think of the ROM as the brain's pre-programmed reflexes. It handles the essential functions that keep the PLC alive and kicking. When you power up a PLC, it's the code stored in ROM that kicks in, runs self-tests, initializes the hardware, and loads the operating system. Without ROM, the PLC wouldn't even know how to start up!

Furthermore, ROM often includes pre-built routines and functions that programmers can use in their PLC programs. These can include math functions, communication protocols, or specialized algorithms. By providing these pre-built components, ROM saves programmers time and effort, allowing them to focus on the unique aspects of their specific applications. It's like having a handy toolbox of pre-sharpened tools ready to use.

So, whether it's booting up the system, managing the hardware, or providing pre-built functions, ROM plays a crucial role in enabling the PLC to perform its automation tasks. It's the silent workhorse, the unsung hero, tirelessly ensuring the PLC operates reliably and efficiently.

Different Types of ROM in PLCs

3. Exploring the Varieties of Read-Only Memory

While the core concept of ROM remains the same — non-volatile, read-only storage — there are actually different types of ROM used in PLCs, each with its own characteristics. These variations exist to meet different needs in terms of cost, programmability, and durability. Let's take a peek at a few of the most common types.

First, there's Mask ROM. This is the oldest type, and it's programmed during the manufacturing process. Its contents are permanently etched into the chip, and it cannot be changed after it's made. Mask ROM is the most cost-effective option for high-volume production runs where the program will never need to be updated. It's like a record pressed with a specific song; you can't change the track list afterwards.

Next, we have PROM (Programmable ROM). PROM can be programmed once, using a special programmer device. This gives manufacturers more flexibility than Mask ROM because they can program the ROM after the chip has been fabricated. Once programmed, however, PROM cannot be erased or reprogrammed. It's akin to burning a CD-R; you can write to it once, but you can't erase it and start over.

Then there's EPROM (Erasable Programmable ROM). EPROM can be erased and reprogrammed, but it requires exposure to ultraviolet (UV) light. This means physically removing the chip from the PLC and placing it under a UV lamp for a specific amount of time. Because of the hassle involved, EPROM is not ideal for applications where frequent updates are needed. Think of it as a chalkboard that needs special equipment to erase; not exactly convenient for daily changes.

Finally, we have EEPROM (Electrically Erasable Programmable ROM) and its more advanced cousin, Flash Memory. EEPROM can be erased and reprogrammed electrically, without removing the chip from the PLC. This makes it much more convenient for updates and changes. Flash memory, a type of EEPROM, offers even faster write speeds and higher storage densities. It's like having a rewritable USB drive built into your PLC.

What’s The Difference Between RAM And ROM? Funtechnow

Why ROM Matters for PLC Reliability

4. The Unshakable Foundation of Consistent Performance

So, why is ROM so important for ensuring PLC reliability? Well, the very nature of ROM, its read-only characteristic, provides a crucial safeguard against data corruption and unauthorized modifications. Because the core system software and essential firmware are stored in ROM, they are protected from accidental or malicious changes that could compromise the PLC's operation.

Imagine if the operating system of your PLC was stored in RAM instead of ROM. A power surge, a programming error, or even a virus could potentially corrupt the OS, rendering the PLC useless or, worse, causing it to malfunction in unpredictable ways. ROM eliminates this risk by providing a secure, immutable storage location for the critical software components.

Furthermore, the non-volatility of ROM ensures that the PLC always starts up in a known and consistent state. Even after a power outage, the PLC will automatically reload its operating system and firmware from ROM, ensuring that it functions correctly. This reliability is especially important in industrial settings, where PLCs are often used to control critical processes that must operate continuously and without interruption. A PLC that can't reliably start up after a power failure is a recipe for disaster!

By providing a stable, secure, and non-volatile storage location for essential software, ROM plays a vital role in ensuring the reliability and robustness of PLCs. It's the foundation upon which all other PLC functions are built, the bedrock of consistent and predictable performance. Without ROM, PLCs would be far more vulnerable to errors and failures, making them unsuitable for many of the critical applications they are used for today.

ROM PLC

5. Weighing the Pros and Cons

Like everything in the tech world, ROM in PLCs comes with its own set of advantages and disadvantages. Understanding these pros and cons can help you appreciate why ROM is used in PLCs and where its limitations lie. Let's explore them:

Advantages:

- Reliability: The read-only nature prevents accidental or malicious data corruption.

- Non-Volatility: Retains data even when power is off, ensuring consistent startup.

- Security: Protects core system software from unauthorized modification.

- Cost-Effective (for Mask ROM): For high-volume production, Mask ROM offers a lower cost per unit.

Disadvantages:

- Limited Programmability: Most types of ROM are difficult or impossible to reprogram after manufacturing.

- Inflexibility: Makes updating firmware and system software challenging or impossible.

- Obsolescence: Older ROM technologies (e.g., Mask ROM) can become obsolete quickly.

- Higher Cost (for EEPROM/Flash): Reprogrammable ROM options can be more expensive.

Ultimately, the advantages of ROM — particularly its reliability and security — outweigh the disadvantages in many PLC applications. However, the trend towards more flexible and reprogrammable memory technologies, like EEPROM and Flash memory, reflects the growing need for easier updates and greater adaptability in modern industrial automation systems.

So, when considering ROM in PLCs, it's important to weigh these advantages and disadvantages in the context of your specific application requirements. The ideal choice depends on factors like the frequency of software updates, the criticality of data integrity, and the overall cost considerations.

FAQ About ROM in PLCs

6. Your Burning Questions Answered!

Still got questions about ROM in PLCs? You're not alone! Here are a few frequently asked questions to clear up any remaining confusion:

Q: Can I reprogram the ROM in my PLC?A: It depends on the type of ROM. Mask ROM and PROM cannot be reprogrammed. EPROM can be reprogrammed, but it requires UV light exposure, which is inconvenient. EEPROM and Flash memory are electrically erasable and programmable, making them much easier to update.

Q: What happens if the ROM in my PLC gets corrupted?A: If the ROM gets corrupted, the PLC will likely become unusable. In most cases, you'll need to replace the ROM chip or, in some cases, the entire PLC. This underscores the importance of using reliable ROM technologies and protecting the PLC from environmental factors that could damage the ROM.

Q: Is ROM used for storing my PLC program?A: No, your user-defined PLC program is typically stored in RAM or Flash memory, not ROM. ROM is primarily used for the PLC's operating system, boot sequences, and other essential firmware.

Q: How do I know what type of ROM is used in my PLC?A: The type of ROM used in your PLC will typically be specified in the PLC's documentation or datasheet. You can also often identify the ROM chip by its part number and look up its specifications online.